U-Panel Bulk bags are designed with 3 separate cloth items however a single piece of cloth is used to form 2 sides together with the bottom of the bag. The opposite 2 sides are then stitched on to this ‘U’-shaped panel and standard four loop bags are suitable for all types of bulk materials.

U PANEL FIBC BAG

4 PANEL FIBC BAG

Four panel bags have seams along four separate pieces of fabrics that are stitched together to construct the body of bags as well as have the top and bottom panels stitch in. Four panel bags have four lifting loops that make transportation of building materials and various raw materials easier.

CIRCULAR FIBC BAG

Circular bulk bags (FIBC) have a circular/tubular body that is seamless with only top and bottom panel sewed into the bag. Circular style bags are ideal for fine and hydroscopic materials..

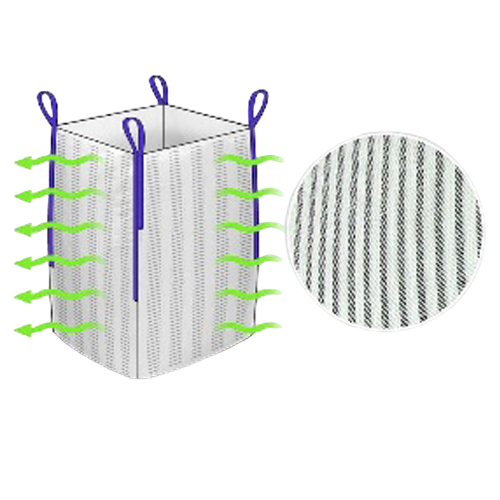

VENTILATED FIBC BAG

Ventilated bags are where the fabric has breathable strips. This is very useful for products that breath while packed and moved especially fruits and vegetables supply chain.

TUNNEL LOOP FIBC BAG

Tunnel loop bags are different from other bags because of its lifting arrangement where in the forklift can itself engage in the loops given to lift the bags with minimal human intervention.

SINGLE LOOP FIBC BAG / DOUBLE LOOP FIBC BAG

Produced from single tubular fabric, the 1-and 2- Loop Bags are widely accepted as being more cost effective than the traditional 4- Loop Bags used.

CROSS CORNER TUBULAR FIBC BAG

Cross-corner loop bag, a bulk bag made of circular woven fabric which is open on a top and has a flat base. It is easy to handle and lift by forklifts and cranes. Made of UV stabilized polypropylene, this cross-corner loop bag is made of a thick fabric which is ideal for building materials such as gravel, Sand, topsoil, etc. These Cross- Corner loop bags are available in various colors and capacity.

PLATTEN BAG

Platten Bag are those bags which are made horizontally with the same characteristics like other FIBC bag along with Loops.

PP WOVEN FABRICS ROLL

PP Woven flat or tubular fabric is available in laminated and unlamented form. These fabrics are used in different industrial segments like Bag manufacturers, Fertilizers, Cement, Polymers, Chemicals, Textiles, Machinery and Food grain packaging.

STRETCH

3P offers stretch film products that provide enduring performance, maximum efficiency and unmatched value. We offer both machine and hand roll film to suit your needs. 3P stretch specialists can assist you optimize your stretch wrapping process to reduce stretch film material costs while improving containment and protection.

Top areas / industries for FIBC bags application

1). Flour, Food Grain, Spices.

2). Sugar, Tobacco.

3). Fertilizer, Cement, Sand.

4). Pharmaceuticals.

5). Petrochemicals, Resins.

6). Minerals, Compost.

7). Carbon Black.

8). Detergent.

9). Agro Chemicals, Salts.

10). Firewood.

11). Granules of Plastics.

SPECIFICATIONS & OPTIONS :

Above Product are Available in Different Type & Attachment as Under.

SWL : 500 kg to 2000 kg.

SF : 5:1 / 6:1 / 7:1

Lifting :One loop, Two loop, Four loop, Tunnel loop. Loops made from pp available in various colors & designs.

Filling : Filling spout, Skirt , Flap, Iris (Pyjama), Star closer (Pattle closer)

Discharge : Discharge spout, Skirt , Flap, Iris (Pyjama), Star closer (Pattle closer) & Conical.

Liner :With or without liner. Liner comes in Loose / Tabbed / Stitched .

Printing :Printed and unprinted (Up to 4 colors).

Sewing :Hiracle & safety, double chain with dust proof. Thread is use various colors like blue, black, white, green & red.

Fabric: Flat plain-woven or Circular plain-woven cloth with coated or uncoated.